NOAA Teacher at Sea

Staci DeSchryver

Onboard NOAA Ship Oscar Dyson

July 26 – August 12, 2011

Mission: Pollock Survey

Geographical Area of Cruise: Gulf of Alaska

Location: Barnabas Strait 57 deg 22.630 N, 152 deg 24.910W

Heading: 67.8 deg

Date: August 9, 2011

Weather Data From the Bridge

Partly Cloudy Skies

Temp: 13.5 deg

Dewpoint: 6 deg

Barometric Pressure: 1020 mb, falling, then steady

Wind: 240 deg at 12kts

Seas: Calm

stn model 08.11

Science and Technology Log

The start of my first official shift onboard the Oscar Dyson was an interesting one! We had lost some time (11 days) to some complications, so our cruise goals shifted a bit from the original plan. We had to focus on the most important aspects of the mission, and sacrifice carefully, as it wasn’t plausible to complete the entire mission in the time allotted. One of the major steps for completing the season was to do what is known as a calibration. In order to save time, we did the calibration on my first night out on the job!

Calibrations are typically done during the daytime because the fish are curious little beasts. During the day, they move lower in the water column, and therefore do not interfere with the calibration of the system, mainly because they are so far away they are oblivious to it. At night, however, they party at a shallower depth, and sometimes their acoustic signatures can mar the data collected during a calibration. It is critical to the scientists that they calibrate the acoustic system accurately, and if there is a school of fish swarming the calibration tools, well, it’s a big ‘ole mess. Given that we are on a shortened time schedule, it made practical sense to conduct the calibration overnight.

Why do we calibrate the acoustic transducer? Think of it like this. Have you ever baked cookies before and followed the directions to the letter, only to have them come out of the oven like crispy critters or balls of goo? Or, let’s say, you have a favorite recipe you use all the time, and you gave the recipe to a friend who makes the same cookies the same way, yet complains that they are overcooked? Well, one of the reasons that the recipe may have not turned out was because either your oven, or your friend’s oven was not properly calibrated. Let’s say, for example, the recipe calls to bake the cookies at 350 degrees for 15 minutes.

If you turn the dial to 350 degrees, it is reasonable to expect that the oven is, in fact, 350 degrees. But there is an equal possibility that the oven is actually only 325, or maybe even 400 degrees. How would you double check to see if your instrument is off its mark? One solution is to heat the oven to 350, and use a meat or candy thermometer that you know has an accurate readout and then put the thermometer in the oven. If the candy thermometer reads out at 350, you can be certain that your oven really is 350 when you turn it on. If the candy thermometer reads out at 375, then you can be certain there’s an error in the readout of your instrument. Calibration corrects for those errors.

Calibration on this survey is important because scientists use information from the acoustic transducer to determine the types and abundance of organisms in the water column. If the instrument they use to make these predictions is off in any way, then all of the data they collect could be determined to be insufficient or unreliable. Calibration also ensures that acoustic measurements (and survey results) are comparable between different cruises, locations, and times.

Calibration is done much in the same way as an oven is calibrated. We take an object that has a known and reliable return rate on the acoustic transducer, and hang it below the ship. Then, the scientists will “ping” acoustic soundings off of the object and see how well the return matches up with the known return rate. If it’s off, then they can “tune” the transducers, much like a guitar is tuned.

It is only necessary to calibrate the transducers twice per survey – once at the beginning of the survey (one was done in June) and one at the end of the survey (which was now). When the transducer is calibrating, the ship must be as close to stationary as possible. This is why the lead scientist chose to do the calibration at night – we can’t calibrate and conduct assessment surveys at the same time. Therefore, it’s a one-pony show when the transducer is calibrating. Almost all other scientific field work ceases while the calibration is completed.

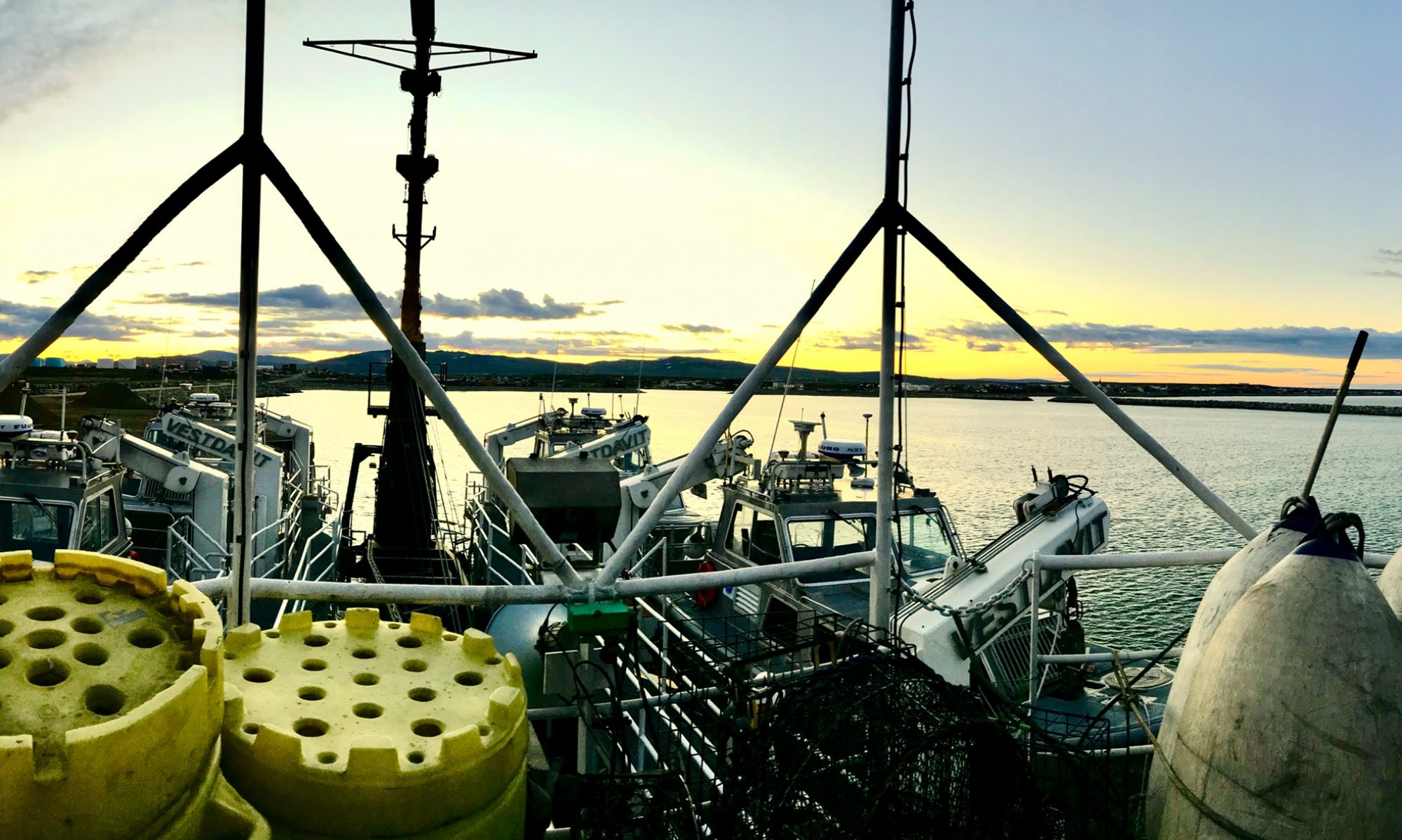

There are two materials used for calibration for this particular transducer on the Oscar Dyson. The first is Tungsten Carbide, and the second is pure Copper. These small, spherical objects are quite cleverly hung below the ship off of three downriggers attached to the port and starboard rails. In order to hang the spheres, the strings on either side of the ship must connect. In a sense, we ask the Dyson to “jump rope” to get the calibration sphere underneath the ship in the correct position.

Calibration takes about six to eight hours to complete. I got to help with setting the downriggers up, changing out the calibration spheres, and breaking down the equipment. As it turns out, the transducer only needed minor adjustments this time, which is pretty typical for the ship. However, it’s important to double check so that if there is a problem, it can be detected early and corrected.

Personal Log

Today, the chief engineer of the ship, Jeff, gave us a tour of the engine room. Holy cow, was that impressive! I don’t know what I was thinking when I thought that the guts of this beast were contained in one small room. They most decidedly are not. There are two whole decks below the lowest level I know of – and they are filled with all kinds of interesting equipment. We got to see all of the engines (there are 4 diesel generators), where the water is purified for consumption, and all of the internal components of the winch system that lowers and raises our fishing nets. As if that weren’t enough, we popped open a floor hatch, climbed down the ladder two flights, and got to stand right on the “skin” of the boat. Translation: The only thing separating my feet and the big blue sea was a thin little piece of metal. It was so cool. The ship is designed to be “acoustically silent” – like a stealth fighter, except they don’t call it stealth and we aren’t fighting enemies – we are hunting fish. Because of this, many of the larger pieces of equipment are hoisted up on platforms that silence their working parts. The ship has diesel-electric propulsion.

This means that there are four diesel generators that make electricity, which then gets split into two different forms – one type is for propulsion, and the other is for our lights and other conveniences. It sounds really complicated, and much of what the engineers do on board is quite complicated, but everything onboard is smartly labeled to help the engineers get the job done. I also learned today what the funny numbers on all of the passage doors mean. See the caption for a description.

One thing that Cat and I were discussing this morning while searching through binoculars in Alitak Bay for interesting woodland creatures was that we can go pretty much wherever we want to go on this ship. Everyone who works and lives here is so friendly and welcoming. They answer any of our questions (even the silly ones) and they all have such cool life stories. What’s better is that everyone is willing to share what they’ve learned, experiences they’ve had, and accomplishments they’ve achieved to make it here. I am aboard a utopian city bursting with genuine people who love what they do. Now, please understand that it’s not that I ever expected the opposite for even a single second. The science and technology is definitely neat, but the people who live and work here are what is making this trip a once-in-a-lifetime experience.

Do you know….

Your Ship Superstitions?

1. Bananas on a boat are considered bad luck.

2. Black luggage for sailors is considered bad luck.

3. One should never whistle – especially on the bridge or in the wheelhouse – you may whistle up a storm.

4. To see a black cat before boarding is good luck.

5. Dolphins swimming along the ship are good luck.

6. Never sail on Friday – it’s unlucky.

7. Never sail on the first Monday in April – also unlucky.

8. Never say the word “Drown” on a ship, as it encourages the act.

9. Sailors should avoid flat-footed people – they are bad luck.

10. Never step onboard a ship with your left foot first.